Index Speed: 2500/hour

Index Accuracy: Below +/- 5 microns

No Compressor required

Quiet and smooth

Mechanical Squeegee Pressure Equalizer

Built to Print 24/7 Non-stop

Single Phase, Plug & Play

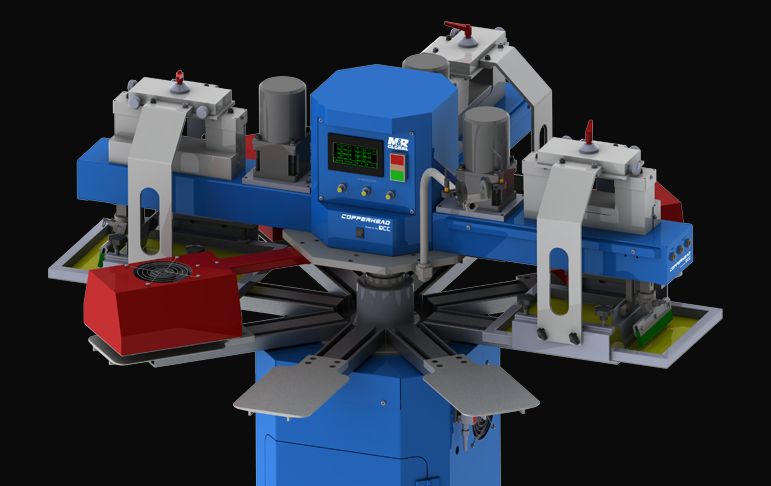

Compact & space-saving

| No. of Colors | 1 | 2 | 3 | 4 |

| Stations | 8 | 8 | 8 | 10 |

| Max Image Size | 6"x6"(15 x 15 cm) | 6"x6"(15 x 15 cm) | 6"x6"(15 x 15 cm) | 6"x6"(15 x 15 cm) |

| Max Image Size (OD) | 11"x 15" (28 x 38 cm) | 11"x 15" (28 x 38 cm) | 11"x 15" (28 x 38 cm) | 11"x 15" (28 x 38 cm) |

| Standard Pallet Size | 6" x 12" (15 x 30 cm) | 6" x 12" (15 x 30 cm) | 6" x 12" (15 x 30 cm) | 6" x 12" (15 x 30 cm) |

| Profile thickness ( Min - Max ) | 1" - 1.5" | 1" - 1.5" | 1" - 1.5" | 1" - 1.5" |

| No. of Flash | 3 | 3 | 3 | 4 |

| Flash Curing Area | 6 X 6" ( 15cm X 15cm ) | 6 X 6" ( 15cm X 15cm ) | 6 X 6" ( 15cm X 15cm ) | 6 X 6" ( 15cm X 15cm ) |

| Electrical Specifications* | 208-230V,1-Ph,50/60Hz, 4.8kW, 27A | 208-230V,1-Ph,50/60Hz, 4.9kW, 27A | 208-230V,1-Ph,50/60Hz, 5kW, 28A | 208-230V,1-ph,50/60Hz, 6.6kW, 36A |

| Squeegee Rubber Specs | 8 x 30 mm | 8 x 30 mm | 8 x 30 mm | 8 x 30 mm |

| Total Machine Height | 57.56" (4.8ft) | 57.56" (4.8ft) | 57.56" (4.8ft) | 57.56" (4.8ft) |

| Machine Diameter | 55.5" (4.6 ft) | 55.5" (4.6 ft) | 55.5" (4.6 ft) | 57.6" (4.8 ft) |

| Total Weight | 240 kg | 273 kg | 305 kg | 400 kg |

Index Speed: 2500/hour

Index Accuracy: Below +/- 0.005 mm (5 microns)

No Pneumatics, No Compressor required

Quiet and smooth

Available up to 4 colors / 10 stations

Panasonic brushless geared motor with Panasonic drive for index rotation

Three-point registration system with a fine pitch screw to achieve close tolerance registration

Front screen loading for fast and easy setup

Unique pallet arm invented to withstand excess squeegee pressure to achieve better print sharpness and uniformity

The mechanism minimizes breakdowns thus maintains maximum safety while keeping the functionality simple to use

Caster wheel for easy mobility

The machine is built to print 24/7 non-stop

User-friendly touch-screen controls for effortless operation

Programmable multiple index rotation for speciality printing

Programmable squeegee strokes enable to achieve adequate ink coverage on porous fabrics or when using finer screen mesh. It’s also helpful for HD printing and various speciality inks to gain thickness

With adjustable print mode, it’s easy to program squeegee to start from the front to back or from back to the front side or rear side

Single Phase, Plug & Play

Compact & space-saving

Belt free squeegee motion

Panasonic geared motor for squeegee motion

Mitsubishi touch screen controls

Mechanical squeegee pressure equalizer to get uniform and consistent ink deposition with accurate registration all over the print area.

Pallet overload protection system avoids major accidents

Hardened grounded gears and mechanical parts minimize machine noise

The heavy solid steel foundation of the machine reduces vibration while printing to hold fine details while printing at full speed

The compact printhead and flash design allows to reduce the overall diameter of the machine to save production space

Print-flash-print multiple times on the same piece

Customized pallet available with various sizes & shapes for diverse applications

Clockwise or anti-clockwise index rotation

Laser registration guides allow for accurate placement

Cloth detector sensor increases productivity and minimizes downtime